At e5 we make our bread with as few ingredients as possible so it’s important to us to understand every step of where those ingredients come from. This in turn is partly why it’s always been a priority for us to use British flour in our baking as much as possible. However this can be hard task in the quantity we require. This idea led us to the idea of milling our own flour; not only to have more control over where the grains we use come from but to have access to flour milled on site at its freshest, giving us more flavoursome and nutritious bread. Knowing that stone milling is essential for cold extraction of flour causing minimal damage to the vitamins and essential oils present in grains.

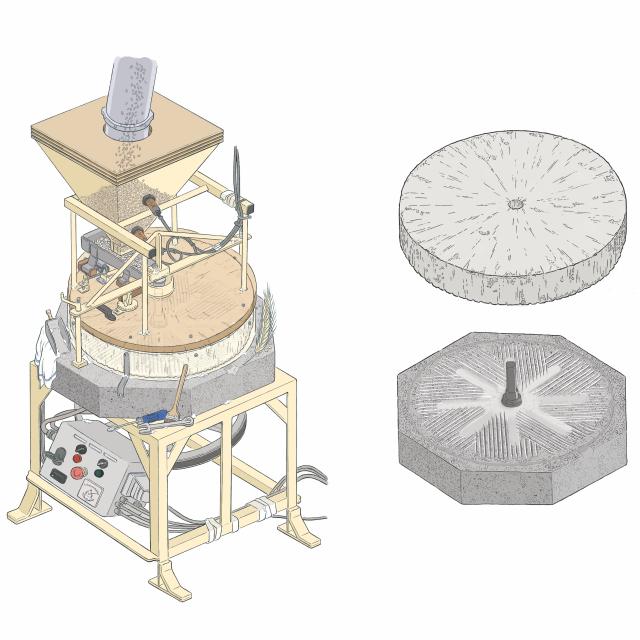

Our mill - Astrié

At e5 Bakehouse we are using an Astrié stone mill, with stones 1m in diameter. The granite for our millstones is quarried in Toulouse, France. The pattern on a millstone is determined by the millwright, and there is much debate about the merits of different patterns. Millstones need to be dressed (re-cut) every 500 tonnes of grain the process. The top granite stone is forced down under pressure, using a simple spring and crank mechanism. The bran layer is peeled off the berry in large chunks as is passes from the centre of the stone towards the edge, finally on the outer edge of the stone the exposed endosperm is ground before being passed to a long rotating screen. This results in a higher extraction whiter flour. The distance between the two millstones is carefully set according to the qualities of the grain in order to shear off the bran and crush the soft endosperm within. The bran is sheared off by 80% of the surface of the stones, while the outer 20% crushes the grain. We further adjust the space between the stones to alter how fine the flour is. Our mill can fill multiple bags. The set up we have now allows 8 bags to fill with approximately 200kg in total of flour.

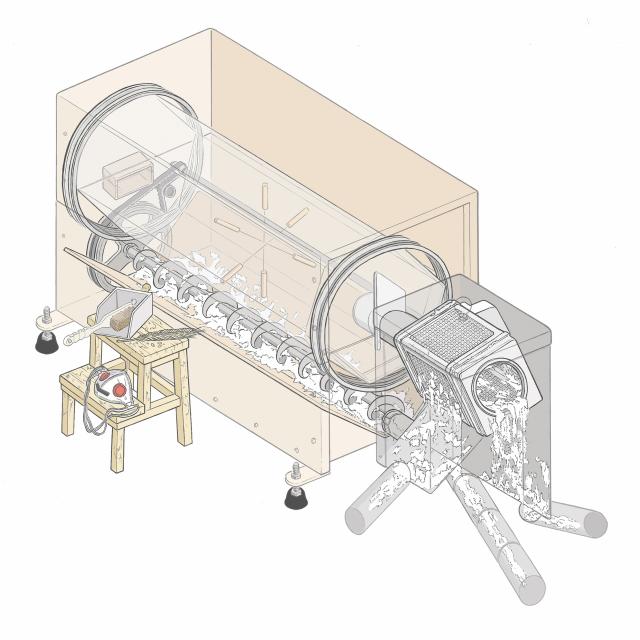

Drum sieve

In the wooden box next to our mill you can find a rotating drum sieve with a 300- (400-, 600-) micro-metre mesh separates the larger bran from the finer flour. The germ, which contains all of the oils and vitamins, is smashed into the flour rather than being separated out as it is in roller milling. Fine pieces of bran also fall through, adding flecks to the creamy white flour. The flour is bagged and stacked, but not for long, as the bakers whisk the flour back off the shelf into the dough.

Grains

In the past it’s been difficult for us to use solely British grains as they naturally have a much lower protein content, which is why there is so much imported grain from Canada and Kazakhstan. It is the protein content in the flour which gives the bread its strength and rise.

We formed strong relationships with farms providing our grains. In creating partnerships with farmers we have access in depth knowledge of growing conditions and soil treatment as well as getting more information on the nutritional values of different types of grain in our breads. Over the last couple of years we started growing a lot of our wheat at Fellows Farm and neighbouring Camp Green Farm. They are both located in Suffolk. We work closely together (bakers, millers and farmers) and decide on what should be grown. After harvest we get some samples that we test-mill and test-bake at e5 to find out if the grains/flour work for us.

The wheat we are growing at Fellows and Camp Green Farm are Miller’s Choice (population of long straw winter wheats), Olande (heritage Danish spring wheat) and Lys Brun (Danish Landrace winter wheat) which we identified as great milling and baking wheat.

Grain delivery

When the grain is received at e5 Bakehouse for us to mill, it is first given a visual check for any contamination. Then the half-tonne totes are raised up on a forklift and emptied into an auger that carries the grains into a silo. Here the stored grain is fed on demand, via another auger, into the hopper of the mill, and an aspirator blows the farm dust and debris off the grains prior to milling. The bran is sheared off and the grain crushed between two millstones. Then a rotating drum sieve separates the larger bran from the finer flour. Finally a series of sacks is filled with flour, each holding about 25kg. The bags are then stitched up and put on adjacent shelves.

Flour

Fresh, stoneground flour is higher in nutrients and fibre than roller milled flour, on account of the germ and parts of the bran entering the flour. This reduces shelf life as the oils can oxidise, but used fresh the flour creates dough that expounds with life and flavour.

Millers talk about extraction rates, meaning the proportion of white flour from the endosperm that is extracted through the sieves from the whole grain. From the baking perspective, a mill which reduces the bran to fine pieces can be an advantage when making wholemeal bread, but for whiter breads the bran cuts the gluten meaning the bread will be flatter and denser, not the result we often want to achieve.

Almost all of the flour we use in our bread is now stoneground, milled on site on our Astrié mill at the Mentmore Terrace arches or delivered weekly from local stone mills. We use the flour when it is as fresh as possible, because once the grains are milled the aromas diffuse from the flour, and the oils start to go rancid.